Around the country, full suspension mountain bikes just haven’t become more popular, they’ve gotten better. The quality of full suspension bikes, especially the design and quality of the rear shocks themselves, have made riding a full squish bike more appealing to more riders on all kinds of terrain.

Of course, that popularity and quality come with challenges in service and complexity. Any given rear shock has between 50 and 150 parts, many of which depend on seals, lubrication, and air to function properly.

Bike Shops Servicing Rear Shocks More Than Ever

That’s led to increase in the number of shocks that need both repair and general maintenance. For years, local bike shops relied on sending in shock rebuilds to manufactures like Fox and RockShox, but turnaround time for factor rebuilds and repairs has extended into weeks or months.

More local bike shops are diagnosing and serving mountain bike rear shocks and forks in-house, which means they need a quick and reliable tool to accurately diagnose the issue and keep their customers rolling.

Shock Hand Dyno to Diagnose Suspension Issues

An experienced bicycle technician can use a rear shock dyno to quickly and accurately diagnose common issues, including:

- Oil-leaks

- Incorrect assembly

- Low or high oil levels

- Debris or low quality oil

- Seal issues

- Loose or broken piston parts

Using a Shock Hand Dyno to Evaluate Repairs

Bike shop technicians can also use the hand dyno to evaluate issues with repairs brought in for other issues. For avid cyclists, a suspension check should be an important part of regular maintenance. It’s an opportunity for the bike shop to further establish expertise and add value to each and every full suspension mountain bike repair.

Bike shops can also use the hand dyno to assure quality on factory rebuilds or new shocks ordered on behalf of customers.

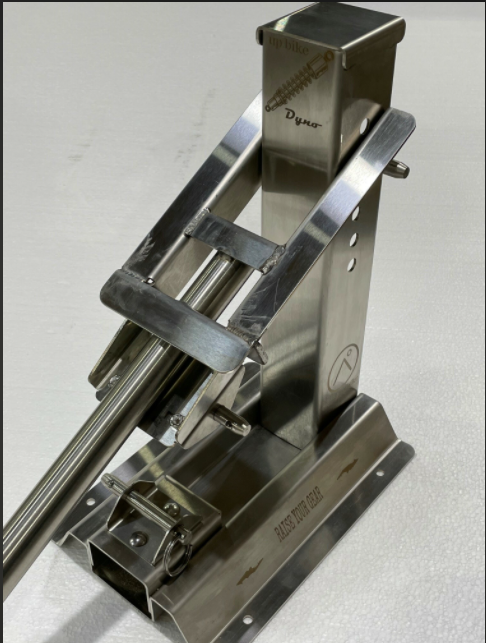

Check out our expertly designed mountain bike shock dyno and let us know if your local shop needs one!